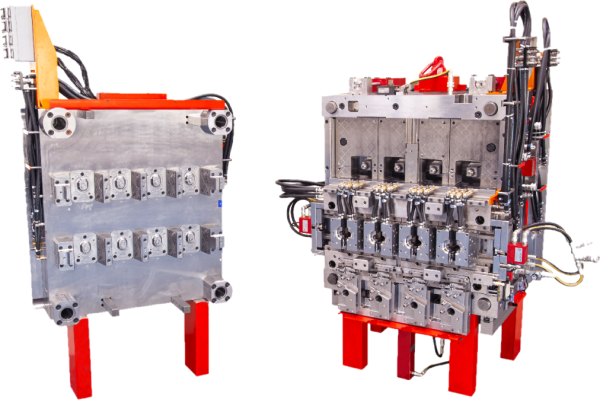

DESIGN AND MANUFACTURING OF MOLDS

For plastic injection, composites and die casting

Product & process feasibility / Innovations

Product co-design and projects monitoring

Design office: 3K design, technical files 2K

Tools manufacturing

Organized in project cells, like our Customers, we have the knowledge and the skills to propose complete plastic solutions integrating the tool, the injection molding machine, the automation and all the necessary means to ensure the required quality.

We became a single key contact for a global service including the expertise and guarantee of the Pernoud Group.

METAMORPHOSE : LE MOULE DE DEMAIN

AUTOMATED AND ELECTRIC VERSION

CHANGE MANAGEMENT

A PROJECT ?

COME AND TEST IT

ON OUR SIMULATOR

AND GET AN ANSWER

IN A FEW CLICKS !

AUTONOMOUS MOLD WITH ELECTRIC ACTUATORS :

- Automated and electric version change management, directly in the mold without stopping the production line

- Gain of flexibility and responsiveness

- Improve your energy yields thanks to fully electric tools, improve cleanliness

- Reduce your storage

- Increase safety by reducing tool handling

- Technical and financial approach proposed by Pernoud: Provider of solutions

- Suitable for low volumes of versions ≤ 40 000 parts / year

CONTACTS

Nicolas Jumel

Key Account Manager

n.jumel@pernoud.com

Hugues Ferre

General Manager

h.ferre@pernoud.com